Electric Stacker In Chennai

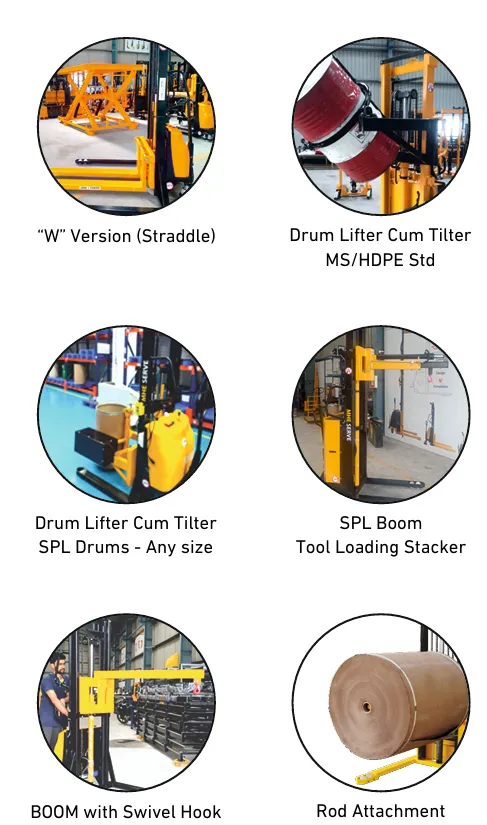

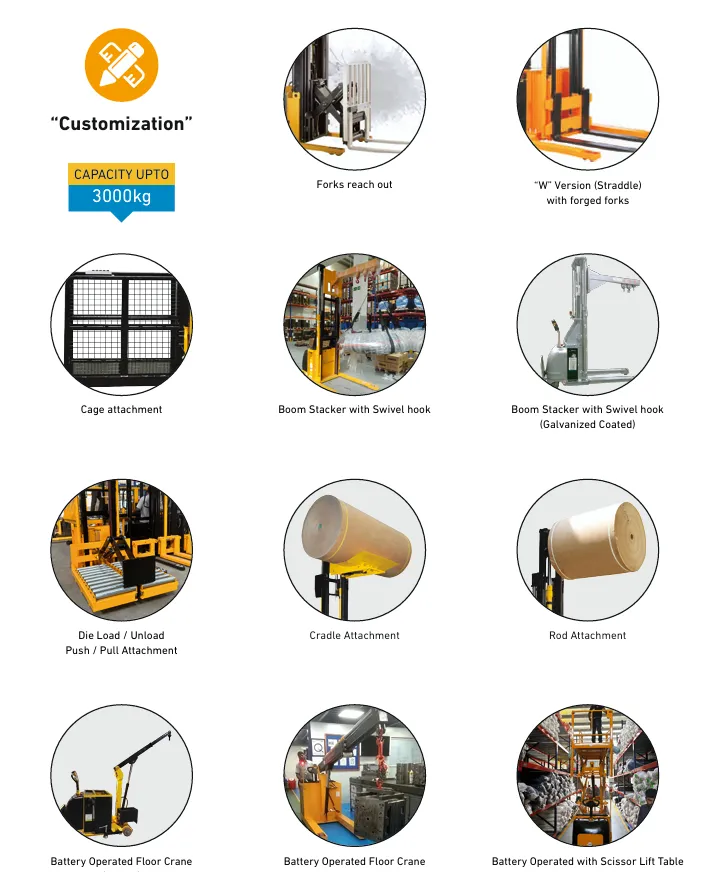

"Customization”

Maneuverable

Smooth manoeuvring with easy-movement wheels

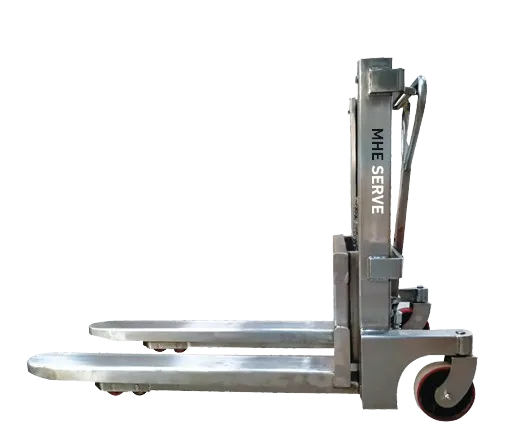

Stainless Steel Stackers

Ergonomic handle for swift operations

Effortless

Ideal for busy gangways, with a small turning radius and compact design

Manual Stackers

Model : HS 10/12/15

Load Capacity : 1000/1200/1500 Kgs

Fork : 1150 x560 / 685 mm

Lowered Height : 90 mm

Raised Height : 1600 mm

wheels : Nylon/PU

Suitable for In-plant Operations where lifting is primary and transport distance is short

Stainless Steel Stackers

"Customization”

Ease of Operation

Enabling easy operations with user-friendly features

Low Operator Fatigue

FRP cover to contain shelf weight, thereby reducing operator fatigue

Easy Parking

Added parking advantage with a foot

Semi Electric Stackers

Model : SES 10/12/15

Load Capacity : 1000/1200/1500 Kgs

Fork : 1150x560 / 685 mm

Lowered Height : 90 mm

Lift Height : Upto 3100 mm

Wheels : Nylon/PU

Powered with electric Lift, essentially used where applications require intensive stacking.

Stainless Steel Semi Stackers

COUNTER BALANCED ELECTRIC STACKE

A perfect Fork lift & Stacker combination. Ideal for ONE VEHICLE DOES IT ALL Operations.

Stability

Featuring side-support wheels for enhanced stability

Safety Features

Enjoy extra safety during operations with a load backrest option

Heavy Duty Battery

Higher battery life, suitable for long working hours

Battery Rollout Option

Time-saving feature to replace batteries on-the-go

"Customization”

Worlds and India Compact counter Balanced stacker Manufactured and Supplied to one of our Valuable Pharmaceutical Clint in India 100 % Customized. Turning radius is 1050mm

FULLY ELECTRIC STACKERS

Versatile, useful in almost all industrial work environments. Its Compact Design and small Turning radius makes it Ideal for operation in narrow aisles and busy gangways. Essentially an in plant Equipment, it is used fro intensive stacking and transportation in minimum cycle times.

1.Versatile stacker, useful in almost all industrial work environment

2.Ergonomically designed for enhanced productivity and safety

3.Ideal for operation in narrow aisles and busy gangways due to compact design and small turning radius

4.Ability to undergo highly intensive stacking and transportation in minimum time

5.Battery Discharge Indicator with pump lockout and hour meter

FURNACE LOADERS

In warehouses where order picking from racks is required, "MECH LIFT" manual electric order pickers are frequently utilized. There is a lifting and lowering semi-battery operated type available. For the operator, it is perfect for quickly and easily recovering things. The operator cabin's remote pad can be used to raise and lower the object with just a button push. The machine is moved manually by pushing on it. This SOP range can also be customized to meet the needs of specific applications and is offered in an A.C. version with flameproof electricals. MECH LIFT's equipment line is highly beneficial to many industry sectors.

FEATURES:

1.Lift height can be customized for application

2.Extra rigid forks minimize deflection and potential damage to furnace “Walkie” Walk-3.behind full power design improves efficiency

4.Fork width and length is built to customer specs

5.Heavy duty steel construction

6.Flexible and Fully Customizable Vacuum Furnace Loader Chassis Design

7.Environmentally Friendly Electric

Battery-Powered Operation:

Electric stackers are powered by rechargeable batteries, providing a clean and quiet alternative to gas-powered equipment. This battery-powered operation reduces emissions and noise, making them ideal for indoor use and environmentally conscious operations.

High Lifting Capacity:

Electric stackers are capable of lifting and stacking pallets and goods to significant heights, often ranging from 1.5 meters to over 5 meters, depending on the model. They can handle a variety of loads, typically up to 2,000 kg, making them suitable for diverse material handling needs.

Precision Control:

Equipped with advanced controls, electric stackers offer smooth and precise operation. The user-friendly interface allows operators to easily manage lifting, lowering, and maneuvering, enhancing productivity and safety in busy work environments.

Ergonomic Design:

Electric stackers are designed with operator comfort in mind. Features such as adjustable handles, easy-to-reach controls, and smooth steering reduce operator fatigue and increase efficiency during extended use.

Safety Features:

Safety is a top priority in the design of electric stackers. These machines often include features like automatic braking systems, emergency stop buttons, overload protection, and stable platform designs to ensure the safety of both the operator and the goods being handled.

Applications of Electric Stackers

Electric stackers are versatile and can be used in a variety of settings, including warehouses, retail stores, and manufacturing plants. They are particularly useful in environments where goods need to be lifted to high shelves or stacked in tight spaces, allowing for efficient use of vertical storage areas.

Conclusion

Electric stackers are a valuable investment for any business involved in material handling. Their battery-powered operation, high lifting capacity, precision control, ergonomic design, and advanced safety features make them an ideal choice for improving efficiency and safety in warehouses, factories, and other storage environments. By reducing manual labor and increasing operational productivity, electric stackers play a critical role in modern material handling strategies.

JOIN MECH LIFT

Part to be our service.

S.No.873, Plot No.45, 1, 2nd St, Anugraham Nagar, Thirumullaivoyal, Chennai, Tamil Nadu 600062